Serpentine spring

Classification:

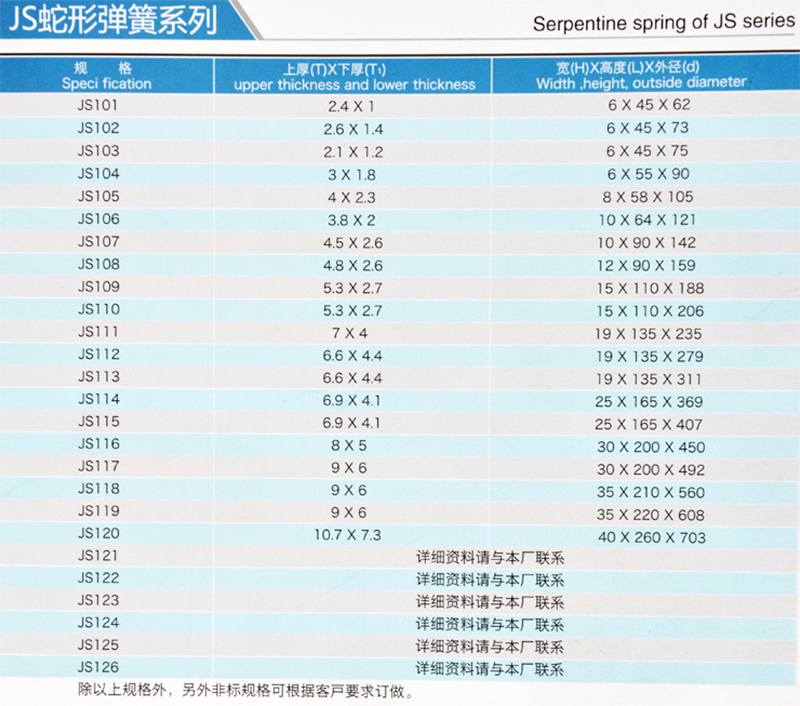

JS serpentine spring

key word:

Serpentine spring

After the serpentine spring is tempered at medium temperature, the compressive stress generated by carbonitriding and the quenching compressive stress are mostly eliminated. At this time, shot peening can improve the surface hardness, eliminate the surface defects, offset the tensile stress generated by the concave surface when the spring is working, and further improve the fatigue limit

Product Description

Shot peening of serpentine spring:

After the serpentine spring is tempered at medium temperature, the compressive stress generated by carbonitriding and the quenching compressive stress are mostly eliminated. At this time, shot peening can improve the surface hardness, eliminate the surface defects, offset the tensile stress generated by the concave surface when the spring is working, and further improve the fatigue limit

With professional technology and standard process, our serpentine spring products have gained high reputation in the serpentine spring coupling industry, and are well received by users

For many years, Zhejiang Junma Spring Manufacturing Co., Ltd. has been committed to researching new processes to improve the performance of the serpentine spring. On the basis of repeatedly studying the heat treatment process of 60Si2MnA, 50CrVA, SAE9254 and other serpentine spring steels, it has improved the heat treatment process of the serpentine spring

Factors Affecting the Quality of Snake Springs:

1. Most of the serpentine springs are damaged by fatigue. Its life mainly depends on the fatigue strength of the spring. The stress of the spring is mainly the alternating bending stress, torsion stress, tension and compression stress, etc. Under the action of the alternating stress, fatigue microcracks begin to form at the defects, and continue to develop inward and then fracture. Therefore, in the process of treatment, the spring surface will form an appropriate hardening layer and generate compressive stress, which will greatly extend the fatigue life of the spring

2. Springs made of hot-rolled spring steel have decarburization and oxidation defects on the surface column (especially silicon manganese steel). The surface of many springs will also be decarburized and oxidized seriously during heat treatment, so that the surface is prone to fatigue damage during use

3. At present, the serpentine spring has twin martensite structure after quenching. The plasticity and toughness of this structure are still low after medium temperature tempering

For many years, Zhejiang Junma Spring Manufacturing Co., Ltd. has been committed to researching new processes to improve the performance of the serpentine spring. On the basis of studying the heat treatment process of 60Si2MnA, 50CrVA, SAE9254 and other serpentine spring steels for many times, it has improved the heat treatment process of the serpentine spring

1. High and medium frequency induction heating is used for carbonitriding to make the spring surface have a carburizing layer with high strength and hardness, so as to improve the fatigue strength of the serpentine spring

2. Austenite grains are refined by high and medium frequency induction heating and isothermal quenching. This will significantly improve the mechanical properties of the serpentine spring

3. Part of lower bainite is obtained by isothermal quenching to further improve plasticity, toughness and fatigue strength

4. The medium temperature tempering is used to change the structure into a mixture of tempered troostite and lower bainite, so as to obtain good comprehensive properties. Our process is not only suitable for silicon manganese pot, chrome vanadium steel, but also suitable for silicon chromium steel, chrome manganese steel and other spring steels

Previous

Next

Previous

Next

Recommended products

Online consulting